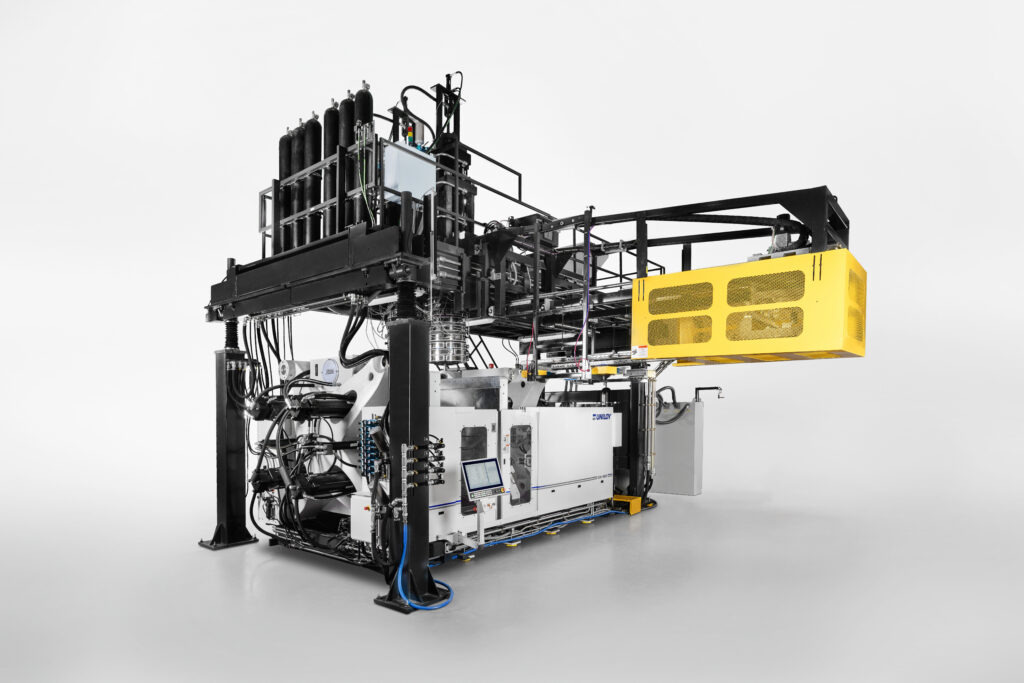

INDUSTRIAL BLOW MOLDING MACHINES [UAI AND UCI.PT SERIES]

Uniloy Accumulator Head technology has always been the best choice for the production of large and heavy parts. It covers the widest range of applications in extrusion blow molding: from industrial packaging to fuel tanks, from toys to nautical and gardening items, from automotive technical parts to flat panels. It is the most versatile extrusion blow molding process and is able to process many types of resin.

Energy savings and the capability of a multilayer co-extrusion are the advantages of Uniloy Parison Transfer models. The Uniloy Industrial blow molding machines follow a modular approach – extruder size, head capacity, clamp force, platens dimensions, and multiple head configurations are also available on all models.

Accumulator Head (UAI Series)

The traditional choice to produce large and heavy blow molded items: from industrial packaging to water tanks, from nautical to gardening items, from automotive parts to flat panels. Robust design and operational reliability, a continuous technological evolution, a wide range of sizes, and the modular approach – extruder size, head capacity, clamp force, platens dimensions can be selected – allows any customer to get the most suitable configuration to his needs.

Continuous Extrusion with Parison Transfer (UCI.PT Series)

The parison is generated by continuous extrusion and fed into the mold cavity by a mechanical device. A technology that brings to most industrial applications the advantages of a better parison profiling, a faster cycle time, a significant energy saving and the capability of the multilayer coextrusion. A wide range of sizes and a variety of configurations (including double head machines with single clamp and single head machines with double clamp) are available to provide the most cost-effective solution.

Accumulator Head with Parison Transfer (UAI.PT Series)

It combines the accumulator head with a manipulator to feed the parison into the mold cavity and makes the extrusion time independent from the cycle time: the parison can be pushed out as slow as needed for a perfect thickness profiling, but as fast as necessary to prevent it from sagging. The ability of coping with long parisons makes this technology ideal for increasing the productivity by vertical alignment of cavities (for instance, to produce double cavity neck-to-neck open top drums).

Accumulator Head with Shuttling Extruder

A unique double-cavity technology based on an innovative layout, where the extruder and the accumulator head are accommodated on a mobile frame running on rails at the upper platform and commuting above two stationary clamps. Compact footprint, no encumbrances on the floor, great accessibility, operational versatility make these double-cavity accumulator head machines ideal for large technical items – both for automotive applications and for “general purpose” blow molded items.

Parison Suction (UAI.SH Series)

The peculiar process for the production of 3-D high-performance seamless ducts used in the air induction systems of the turbocharged engines (automotive sector), available also in the dual-resin configuration (sequential co-extrusion). Uniloy has been a pioneer – in the early nineties – exploring the new opportunities offered by the sequential co-extrusion and the 3-D parison suction process.