MOLDS – Design, Fabrication, R&R

A lot of suppliers can cut cavities in metal. Uniloy goes beyond. We’re a leading supplier of molds for blow molding applications. We offer a wide range of molds expanded with the acquisition of our Fremont location, specializing in wheel, shuttle and extrusion Molds. We have an intimate knowledge of the blow molding process and how to anticipate problems, leverage advantages, and improve your profitability.

3D Mold Prototyping – Uniloy brings your products to life.

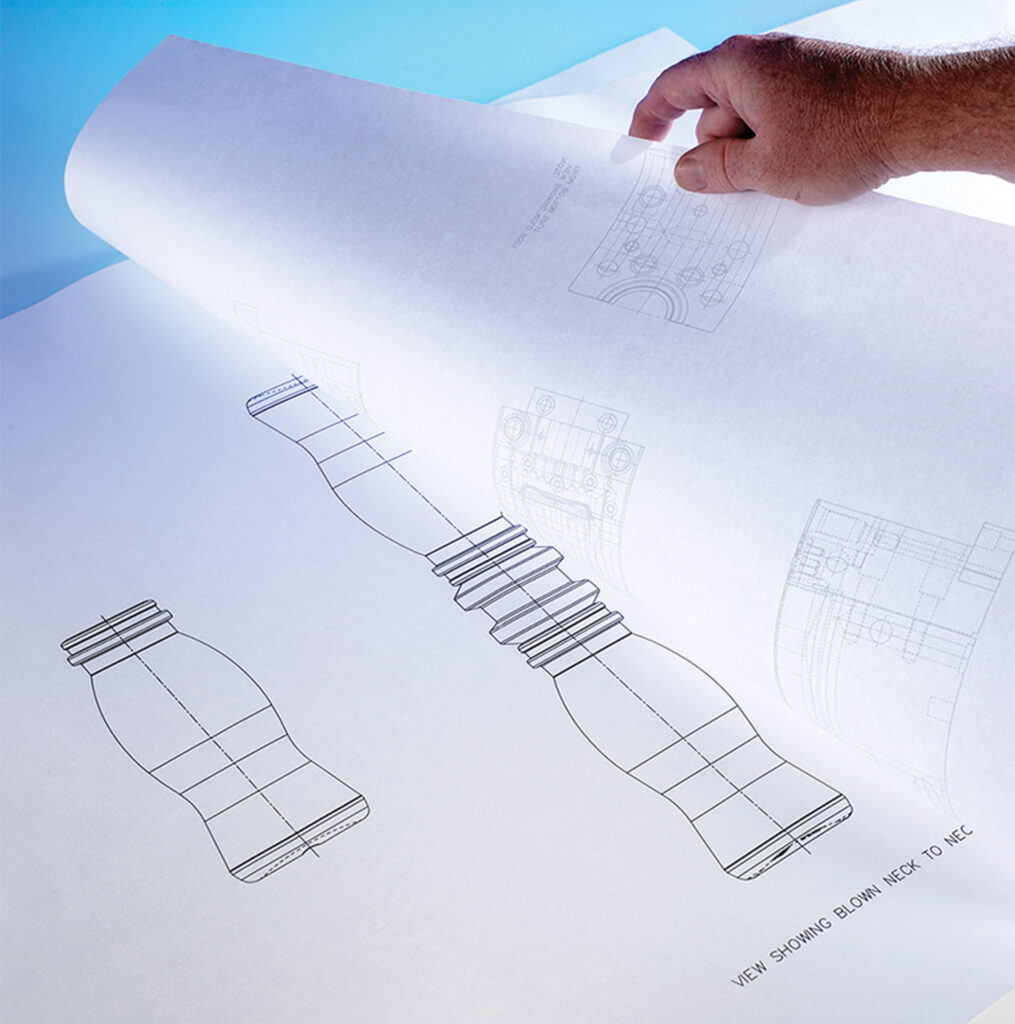

In the hands of an expert, a well-designed part leads to a well-designed mold. Our team of talented designers and engineers can make your ideas a reality, or we can optimize an existing design –quickly and cost-effectively.

Advanced technologies like 3D design software, digital simulation solutions, and our prototype and 3D printing capabilities all help us fast-track development and explore “what if?” scenarios. Digital simulation tools help us analyze container designs to anticipate potential processing and performance issues. We can even deliver lifelike prototypes for market research and focus group studies to optimize your container for consumer appeal. Uniloy can help with light weighting, structural and mechanical integrity and improving aesthetics. Unlike other mold makers only deliver theoretical performance testing, Uniloy offers real-world testing and qualification on the latest machine systems.

Blow Mold Fabrication

Uniloy designs and fabricates the highest-quality tooling needed for your blow-molded applications. Thus, giving you better results, higher quality, and lower costs. Plus, with our 2022 acquisition of nearby mold producer, Century Die in Fremont, we now have the capacity to produce double the number of molds then previous years. At Uniloy, we have the capabilities to meet your needs on-time with consistency.

No other tooling supplier can match Uniloy’s knowledge of blow technologies. Whether you’re running a Uniloy system or not, we can help. Uniloy can manufacture a wide range of molds and tooling, including mold tooling packages for all current Uniloy machine models. We also offer Liberty, Wheel, Continuous Extrusion, Shuttle, Sidel, Krones, Sipa, Krupp and more. Our experience covers a wide range of designs running HDPE, PET, and numerous other resins.

Uniloy10-Step Mold Repair & Refurbishment Program

Are you having quality or performance issues with your molds and trim tooling? Our 10-step R&R process restores all key functionality at a fraction of the cost of new molds. For more specialized needs, or technology upgrades, we can retrofit your molds. Rental molds are available in many configurations to ensure continued productivity while your molds are being serviced.

Watch our video on the Mold R&R Department, located at Uniloy Headquarters in Tecumseh, MI. USA. In the video, our Department Lead, Josh Sloan, explains the benefits and advantages of using Uniloy as your mold refurbishment partner.

Uniloy Mold Rental Program

Uniloy offers a mold rental program for Dairy customers. We have standard half-gallon dairy and one-gallon dairy molds available to rent while your molds are undergoing refurbishment or repairs, eliminating any downtime you could have so you’re able to remain in production.

Contact Us today to learn more about our Mold Rental Program for dairy producers.

Mold Related Tooling

We have designed and manufactured mold related tooling for customers producing household products such as Coolers, Tool cases, Mailbox Posts & Playground Boarders, Automotive components including Fuel tanks, Spoilers and ductwork, non-automotive fuel tanks for ATV, Snowmobile and lawn & garden.